This morning I busted out a random keyboard with the intention of popping a switch out for this little activity.

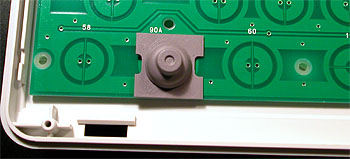

As I was undoing the 400 screws that hold the the Topre PCB to it's mounting plate, I could see strange squarish shapes through the PCB where you'd normally see the tell-tale circular capacitive contact pads. Once I got it apart, well...see for yourself! ( full album here: http://imgur.com/a/sCdxL ):

PCB flipped