Building a foldable, ortholinear scissor switch travel keyboard

Posted: 21 Nov 2017, 14:08

I've happily typed on a Kinesis Advantage for years, but am doing a lot of carry-on-only travel, and I can't say that keyboard is exactly space efficient = )

Unfortunately, I haven't been able to find much in the ergonomic, space efficient wireless keyboard market.

The closest I could find was this "iClever" bluetooth folding keyboard ($30 on Amazon, clones under many brands):

The bluetooth is great, and magnets fold it securely in half, making it very portable (about 10 x 15 cm, 13mm thick).

However, I can't bring myself to tolerate its tiny pinky backspace, esc behind function key modifier, or half-sized braces.

I looked into custom keyboards, but everything I've seen uses mechanical switches, which seem like they'll be too bulky for this application.

(Even Cherry MLs are about 11mm for the bare switch, which would mean a folded arrangement twice as thick as this iClever.)

I couldn't find any posts from anyone here actually making a custom scissor-switch keyboard.

@courtesi floated the idea two years ago: keyboards-f2/does-anyone-know-how-expen ... 12422.html but that's all I could find.

I disassembled the iClever to figure out how complex it'd be to do.

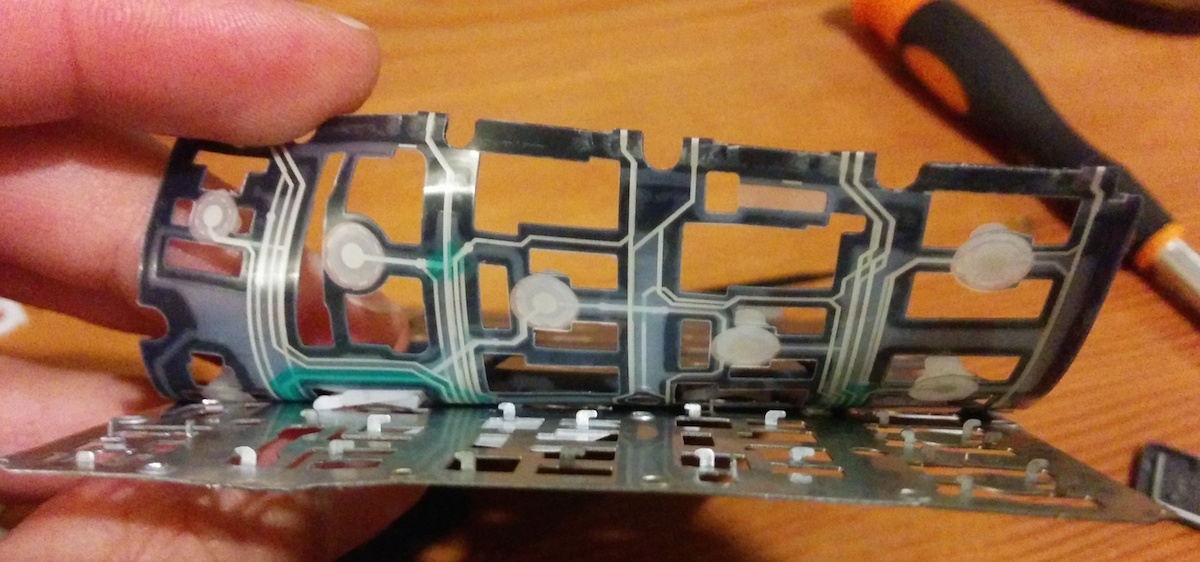

This keyboard is, from back-to-front, an grippy covering, plastic case, a metal backing plate, membrane, and then scissors and key caps:

(grip and plastic casing removed, and as well as few scissors and keycaps)

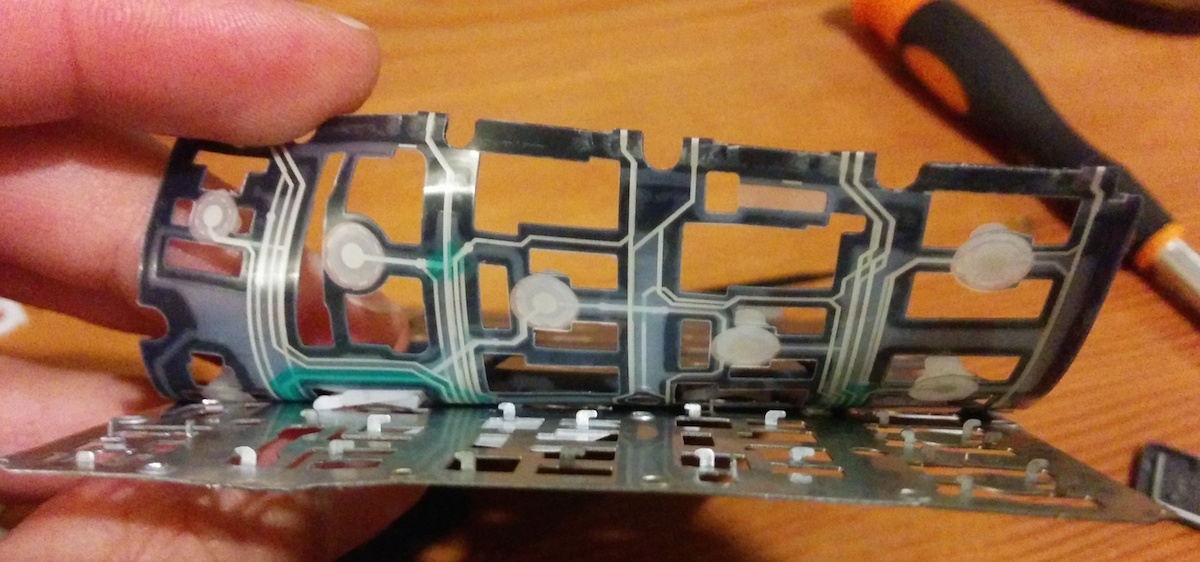

I can't tell exactly what's going on in the membrane:

Why do the traces extend all the way to the edge? (Ease of manufacturing?)

It looks like there are multiple sheets with traces, though I couldn't peel them apart to verify.

The circuit looks fairly straightforward (one connector goes to this half of the keyboard, the other goes across to the other half of the keyboard, which also contains the battery):

So, how difficult would it be to make something like this?

+ Scissors + switches: Can I source these directly somehow, or do I just buy some cheap keyboards from Alibaba and scavenge the mechanisms?

+ Membrane: Seems doable, based on discussion in @courtesi's thread. Hand-drawing conductive ink could be tolerable, especially if I get a microcontroller w/ tons of IO pins such that keys can be wired up directly with no need to do fancy row/col scanning.

+ Backing sheet: It looks like iClever's scissors are mounted on sheet metal that has been punched and then little clips folded up. I'm assuming that only makes sense at scale. For a custom layout, would an SLS 3d print be able to hold the scissor mechanisms in place? Or are there scissors that can be mounted directly to a flat surface?

+ Hardware + Software: The Mitosis keyboard ( https://imgur.com/a/mwTFj ) has broken a lot of ground on this front, hardest part for me will likely be to find a copy of Altium PCB software that I can use here in Australia. = )

Alternative solutions:

+ Just build something w/ low-profile mechanical switches (Cherry ML? Whatever Razor is using in their iPad Pro case?) and get over the folding / super-portability thing.

+ Find the iClever people and see if they'd be willing to do a small run of a variant layout, then pony up $10k ($100k? I have no idea).

What do ya'll think?

Unfortunately, I haven't been able to find much in the ergonomic, space efficient wireless keyboard market.

The closest I could find was this "iClever" bluetooth folding keyboard ($30 on Amazon, clones under many brands):

The bluetooth is great, and magnets fold it securely in half, making it very portable (about 10 x 15 cm, 13mm thick).

However, I can't bring myself to tolerate its tiny pinky backspace, esc behind function key modifier, or half-sized braces.

I looked into custom keyboards, but everything I've seen uses mechanical switches, which seem like they'll be too bulky for this application.

(Even Cherry MLs are about 11mm for the bare switch, which would mean a folded arrangement twice as thick as this iClever.)

I couldn't find any posts from anyone here actually making a custom scissor-switch keyboard.

@courtesi floated the idea two years ago: keyboards-f2/does-anyone-know-how-expen ... 12422.html but that's all I could find.

I disassembled the iClever to figure out how complex it'd be to do.

This keyboard is, from back-to-front, an grippy covering, plastic case, a metal backing plate, membrane, and then scissors and key caps:

(grip and plastic casing removed, and as well as few scissors and keycaps)

I can't tell exactly what's going on in the membrane:

Why do the traces extend all the way to the edge? (Ease of manufacturing?)

It looks like there are multiple sheets with traces, though I couldn't peel them apart to verify.

The circuit looks fairly straightforward (one connector goes to this half of the keyboard, the other goes across to the other half of the keyboard, which also contains the battery):

So, how difficult would it be to make something like this?

+ Scissors + switches: Can I source these directly somehow, or do I just buy some cheap keyboards from Alibaba and scavenge the mechanisms?

+ Membrane: Seems doable, based on discussion in @courtesi's thread. Hand-drawing conductive ink could be tolerable, especially if I get a microcontroller w/ tons of IO pins such that keys can be wired up directly with no need to do fancy row/col scanning.

+ Backing sheet: It looks like iClever's scissors are mounted on sheet metal that has been punched and then little clips folded up. I'm assuming that only makes sense at scale. For a custom layout, would an SLS 3d print be able to hold the scissor mechanisms in place? Or are there scissors that can be mounted directly to a flat surface?

+ Hardware + Software: The Mitosis keyboard ( https://imgur.com/a/mwTFj ) has broken a lot of ground on this front, hardest part for me will likely be to find a copy of Altium PCB software that I can use here in Australia. = )

Alternative solutions:

+ Just build something w/ low-profile mechanical switches (Cherry ML? Whatever Razor is using in their iPad Pro case?) and get over the folding / super-portability thing.

+ Find the iClever people and see if they'd be willing to do a small run of a variant layout, then pony up $10k ($100k? I have no idea).

What do ya'll think?