After thinking long and hard, really what we want is the Total Force of the press.

But what does that mean?

For those that remember integration from high school.

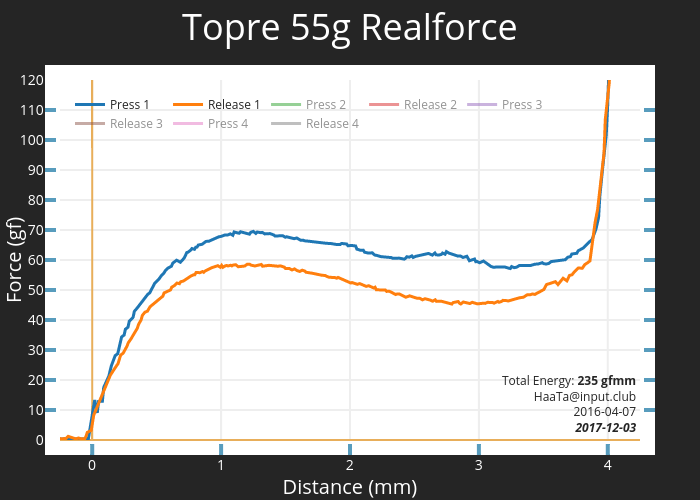

For those who don't remember what that means. We just multiply the force at every point between 0 mm and the bottom-out position (e.g. 4 mm). More simply, this can also be read as the area under the force curve.

Using this, we can derive our new Total Force unit.

Bonus points, anyone who remembers Physics will notice that this is also the same unit for Torque (doesn't mean the same thing though).

Now that we have a measure to compare switches, let's use it!

(remember, you can click on the images to get the interactive graphs)

I leave the analysis to you guys, but notice how the difference between 45g and 55g is much higher than between 30g and 45g.

One of the nice things about how I've implemented my force gauge, I can use numpy (Python library for scientific analysis) to add whatever sort of analysis I want. I just need to come up with the algorithm to apply it to switches in general (that's tricky, but it can be done).

The measurement I use is the average across the 4 different presses rather than just measuring the first one.