Any estimations when this GB will start? (I personally really don't want to sacrifice an Model M if I could just wait a few weeks - but probably it will take longer

FSSK v1.00 - Installation & Users Manual

- Phenix

- -p

- Location: Germany, Cologne

- Main keyboard: F122, soarer´d|Novatouch-s

- Main mouse: Roccat Kone Pure|Rollermouse

- Favorite switch: BS F|Topre-s

- DT Pro Member: -

ok, thanks for.

Any estimations when this GB will start? (I personally really don't want to sacrifice an Model M if I could just wait a few weeks - but probably it will take longer )

)

Any estimations when this GB will start? (I personally really don't want to sacrifice an Model M if I could just wait a few weeks - but probably it will take longer

- shreebles

- Finally 60%

- Location: Cologne, Germany

- Main keyboard: FaceW 45g Silent Red /NerD60 MX Red

- Main mouse: Logitech G303 / GPro (home) MX Anywhere 2 (work)

- Favorite switch: Silent Red, Old Browns, Buckling Spring,

- DT Pro Member: 0094

Yes, that's the difficulty with M's. Most don't want to open a working SSK, which is fine.

But then you could butcher an M and cut it down. It works, but why cut apart a working keyboard?

I have two working Ms and could use them for the mod.

Finding a broken M is the difficult part. Most of these are sold in working order, they are that durable.

PS: I understand it would become cheaper with more orders. But if you look at a complete "new" metal FSSK + new barrels + new flippers etc. you'll probably reach 200-250€ which will put it dangerously close to "complete brand new F62/F77" territory.

But then you could butcher an M and cut it down. It works, but why cut apart a working keyboard?

I have two working Ms and could use them for the mod.

Finding a broken M is the difficult part. Most of these are sold in working order, they are that durable.

PS: I understand it would become cheaper with more orders. But if you look at a complete "new" metal FSSK + new barrels + new flippers etc. you'll probably reach 200-250€ which will put it dangerously close to "complete brand new F62/F77" territory.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Your wording here immediately made me think of something I hadn't until now for Phenix. Technically, there is no reason you can't just bolt mod your regular M with this FSSK PCB. You will obviously have a non-functioning 10-key, but it would buy you time. Its been a while since I have looked at a regular M, but I believe the bolt mod is identical over the portion where the PCB would be. Someone would have to validate that

For the drop in replacement, we could do it for less for sure. When we start talking about replacement cases, that is where the cost creeps in. Also, if people just wanted parts (all assembly required, or at least portions), you would certainly save on labor. It is really hard to know until we really get our minds around all of it with part quotes.

I started to write the longest post in the history of this forum about this

Even in its current form, I would be shocked if you could have something in your hands before the start of 3Q

- Phenix

- -p

- Location: Germany, Cologne

- Main keyboard: F122, soarer´d|Novatouch-s

- Main mouse: Roccat Kone Pure|Rollermouse

- Favorite switch: BS F|Topre-s

- DT Pro Member: -

Oh

don't worry, Ill wait.

Chopping down an Model M is (in general) fine, but if you are going to design an nice case (or the interior parts) on the next months Ill probably just wait.

that s way less stress for me+ the case will (if there's an GB) look better than if I try chopping a case(and even be sturdier)

typos due to my touch screen are possible

don't worry, Ill wait.

Chopping down an Model M is (in general) fine, but if you are going to design an nice case (or the interior parts) on the next months Ill probably just wait.

that s way less stress for me+ the case will (if there's an GB) look better than if I try chopping a case(and even be sturdier)

typos due to my touch screen are possible

- need

- Location: United Kingdom

- DT Pro Member: -

Does that mean a non-chopped model M would work with the FSSK PCB?lot_lizard wrote:shreebles wrote: Technically, there is no reason you can't just bolt mod your regular M with this FSSK PCB. You will obviously have a non-functioning 10-key, but it would buy you time. Its been a while since I have looked at a regular M, but I believe the bolt mod is identical over the portion where the PCB would be...

Sorry for the noob question, but if I'm too lazy to chop the ten key on a standard model m, can I just leave it there and still have the FSSK mod working like it's supposed to?

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

Remember, idollar is testing the first FEXT PCBs right now. That would probably be most appropriate for those who are okay with a full size keyboard.

- ramnes

- ПБТ НАВСЕГДА

- Location: France

- Main keyboard: KMAC LE

- Main mouse: Zowie AM

- Favorite switch: GPL 104 lubed 62g nixies

- DT Pro Member: -

My FSSK PCB arrived today, and that thing is really nice.

I expected it way thicker, but I now understand why it can be bent!

Small problem thought: the upper left corner is broken.

No big deal I guess (and I hope), but still a bit sad about it.

By the way, I got Andreas note.

I expected it way thicker, but I now understand why it can be bent!

Small problem thought: the upper left corner is broken.

No big deal I guess (and I hope), but still a bit sad about it.

By the way, I got Andreas note.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

Sorry for that ramnes, I tried to pack them the best that I could, but you know how the shipping guys are.

There are no traces in this part of the PCB. I do am sure that it will not be a problem, but if you want to get one of the spares that I have, you just have to tell me. I will send it to you.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

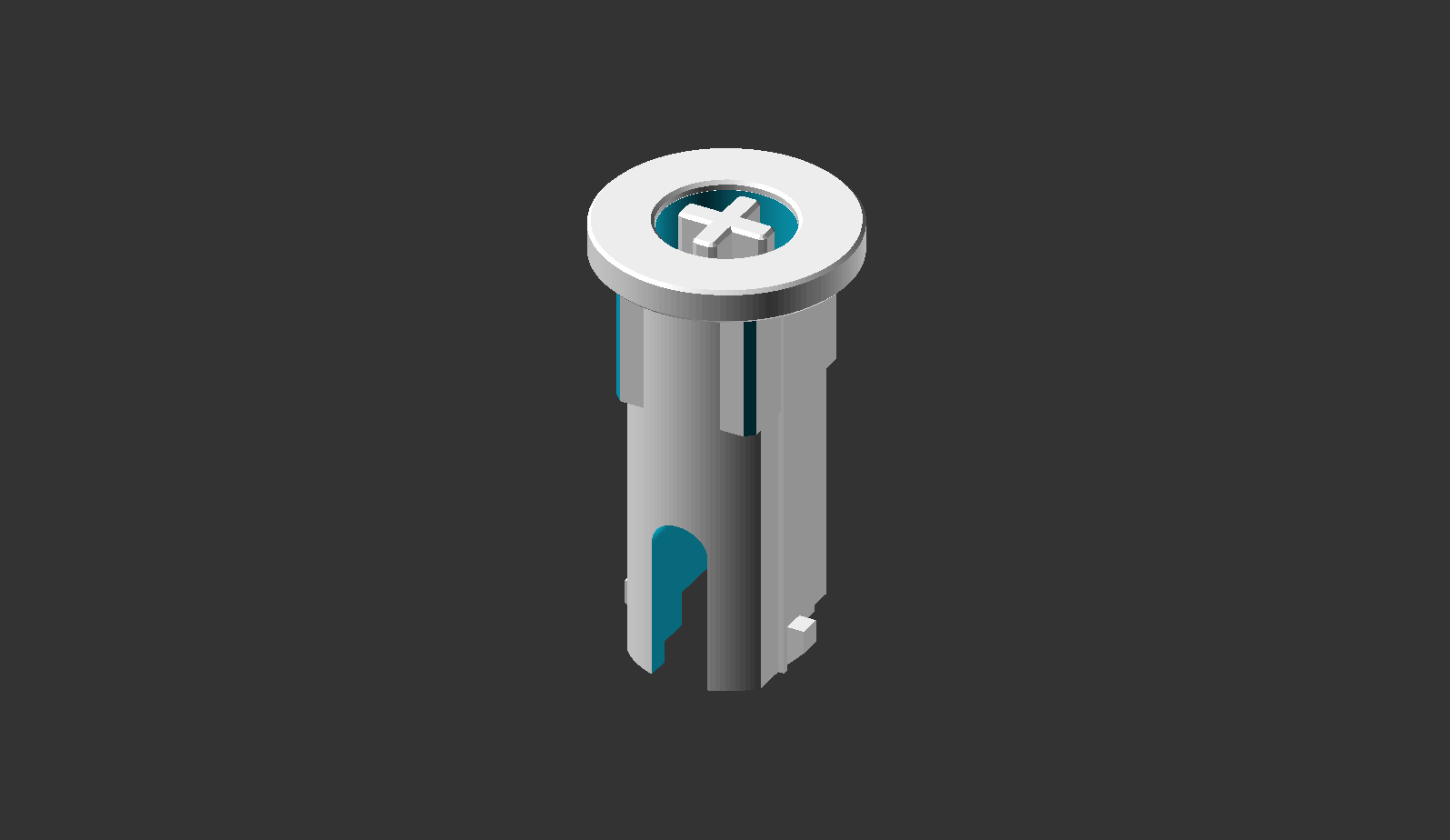

I have a new surprise... a Bucking Spring / Cherry MX keycap adapter. This would let you use alternative keycaps on our FSSK (or any model M/F)

I was going to post everything in this thread, but found a thread matt3o created before, and made the post there. I am having the revision printed with my other order. I think ultimately, that would be my dream board (what we are working on here with the FSSK, with modern artisan double shots).

workshop-f7/buckling-spring-with-cherry ... ml#p304474

EDIT: Added the following linked photos here to save having to hop threads

EDIT: They brought up on the other thread that since the IBM board is curved, and the Cherry is flat, that we might need to get identical key profiles for the board. I played with it a bit, and I am personally happy with the unique pitches. Since the keystems are really the for this project, I am tagging the post here. Its interesting

workshop-f7/buckling-spring-with-cherry ... ml#p304786

I was going to post everything in this thread, but found a thread matt3o created before, and made the post there. I am having the revision printed with my other order. I think ultimately, that would be my dream board (what we are working on here with the FSSK, with modern artisan double shots).

workshop-f7/buckling-spring-with-cherry ... ml#p304474

EDIT: Added the following linked photos here to save having to hop threads

Spoiler:

workshop-f7/buckling-spring-with-cherry ... ml#p304786

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Added a spacebar Cherry MX adapter, and will work on the other special keys next. The only reason I continue to mention here, if it pans out, I might beg i$ to create a PCB that is more friendly to these Cherry Mount special keys later (capslock is going to be ugly), and I plan on using them for the FSSK prototype I am having printed (at least a few). All future updates to the adapter(s) will be in the other thread only... I promise

workshop-f7/buckling-spring-with-cherry ... ml#p305401

Images added to avoid a hop

workshop-f7/buckling-spring-with-cherry ... ml#p305401

Images added to avoid a hop

Spoiler:

- alh84001

- v.001

- Location: EU-HR-ZG

- Main keyboard: unsaver

- Main mouse: logitech m305 / apple trackpad

- Favorite switch: BS

- DT Pro Member: -

I just saw the renders now, as I've been postponing reading this thread for when I get the controller. Give lot_lizard a barrel of coffee and lock him in a room with a computer. I expect fully working, true to original, blue alps replicas in two weeks time

Lot_lizard did you look at the XTant thread? I get what you want to do and why, but simplified approach could suite some of us better. Can you use current work to provide a simplified file for just the top plate, with XT like barrel holes, but the plate otherwise being flat? I can get these made relatively cheaply (1.25mm thick for some $25), and then take them to another place to bend them (and straighten them in the process, since laser cutting induces heat which deforms steel a bit; it's cheaper than water cutting though, and precise enough). Flat back plate with holes that match some of the holes in the PCB would be nice too, if easy to make, but that one is much simpler and easier to measure, so that even I can do it, so don't loose time on it if not necessary

In any case, I'll first use my cut model M plate and frame, just to see and hear what the fuss is about . Then I'll see if I want to F-ify it more.

. Then I'll see if I want to F-ify it more.

Lot_lizard did you look at the XTant thread? I get what you want to do and why, but simplified approach could suite some of us better. Can you use current work to provide a simplified file for just the top plate, with XT like barrel holes, but the plate otherwise being flat? I can get these made relatively cheaply (1.25mm thick for some $25), and then take them to another place to bend them (and straighten them in the process, since laser cutting induces heat which deforms steel a bit; it's cheaper than water cutting though, and precise enough). Flat back plate with holes that match some of the holes in the PCB would be nice too, if easy to make, but that one is much simpler and easier to measure, so that even I can do it, so don't loose time on it if not necessary

In any case, I'll first use my cut model M plate and frame, just to see and hear what the fuss is about

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Hahaha... Thanks

I am very familiar with it, and have huge respect for wcass's work. Let me get the prints back and confirm fit (ship 5/13). I would be happy to share plans afterwards. I already have a flat (pre rolled and broke) DXF that I sent to Phosphorglow to die cut foam for me for the printed protoype. Once I confirm the entire assembly works, I will make metal plates as well with the help of machine shop friends I have (similar to the approach you describe). And agreed, the cutting process selection is not a big deal. Water cutting has a LARGE upside of cutting several sheets at once much more cleanly. Regardless, you will want to cold roll and break after cutting. I actually plan on doing the rolling (the radial bend) and breaks (90 degree bends) myself. I have a nice shop out back. This design was meant to be easily produced by a typical metal processor, and I'm happy to share. My work will be 100% public

The CAD plans are needed for a bigger vision to come... Stay tuned

EDIT: regarding the interior screw mounts through the PCB. I am very confident at this point that it is not necessary via tests and just physics. It is very important that the top plate be a lower radial bend (more curved) than the bottom plate. Even as small of a difference as 5mm will be plenty. The down pressure of the bend makes a few screws passing through the equivalent of throwing a match on the sun. I believe the only reason the original F had the 2 pegs holding the PCB to the backplate was to secure the PCB during the assembly process

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

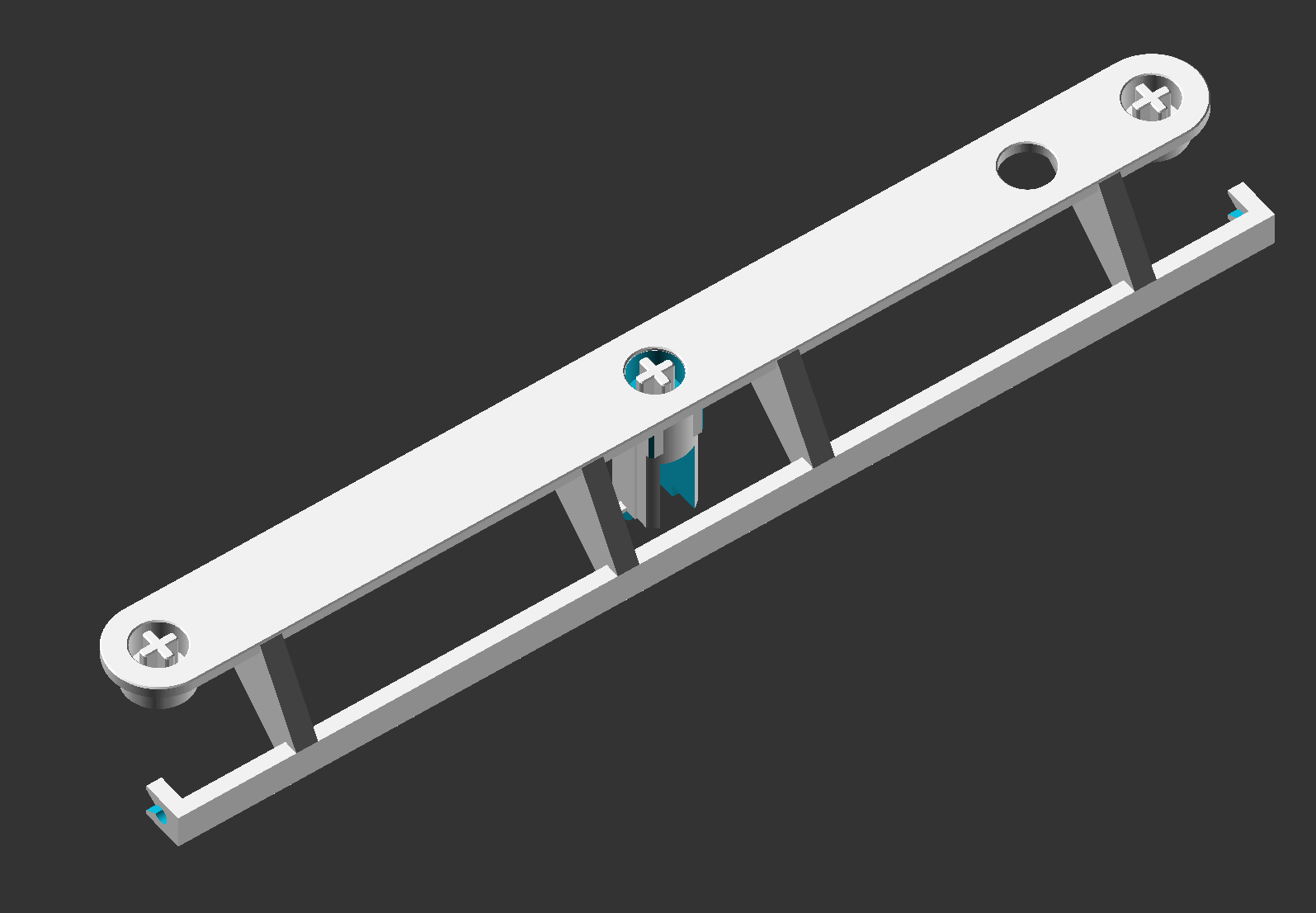

Sorry for the long post, but I have some nice progress to report. When I came home yesterday evening, I had two wonderful little packages waiting on my doorstep. The Shapeways plastic prints had arrived (minus the barrels, flippers, and Cherry keystem adapters), along with the foam that Maxx (Phosphorglow) was awesome enough to die cut for me. AGAIN... the goal of the printing is to test the fit... NOT act as a long term deliverable

Shapeways strong and flexible takes paint nicely, and thought it would help visualize the stacked plates, so I put one coat on with a high volume low pressure paint gun. I will let you take a guess at what the SSK case the final version will go into at some point  ... The colors were color matched a couple of weeks ago

And finally, the assembly plates with barrels and foam. I still need to secure the plates together with screws (will be different for the plastic prototype than the eventual metal version due to the lack of strength of the plastic by comparison... ie... no tapping for a screw). Also, I am not sure if we will design the barrel "locks" differently vs. the round peg used by the XT/Bigfoot, but what I had on hand in bulk for the test.

EDIT: Added a picture of the barrel fit on the backside of the top plate as I thought it might be interesting

All in all... very pleased. I will finish assembling the unit with screws and the PCB, play with it for a couple of weeks as my daily driver (it is rigid enough to be fully functional), and make any tweaks that are discovered along the way.

... The colors were color matched a couple of weeks ago

And finally, the assembly plates with barrels and foam. I still need to secure the plates together with screws (will be different for the plastic prototype than the eventual metal version due to the lack of strength of the plastic by comparison... ie... no tapping for a screw). Also, I am not sure if we will design the barrel "locks" differently vs. the round peg used by the XT/Bigfoot, but what I had on hand in bulk for the test.

EDIT: Added a picture of the barrel fit on the backside of the top plate as I thought it might be interesting

All in all... very pleased. I will finish assembling the unit with screws and the PCB, play with it for a couple of weeks as my daily driver (it is rigid enough to be fully functional), and make any tweaks that are discovered along the way.

Spoiler:

Spoiler:

Spoiler:

Spoiler:

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Omg metal version would be amazing...

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Thanks everyone for the feedback... its been a fun journey. I am happy to report that I am currently typing from it (though the plastic is too wobbly in the middle of the board to be desirable for a long term solution).

Started with bending the PCB (I had a REAL need to do so since any undesirable pitch in the PCB alters the entire assembly since the plastic is so flimsy). I have a heat gun (which makes short work of it), and needed the complete curve to be uniform. I used a 4 gallon ceramic crock to achieve the desired bend. Worked beautifully

Then the assembled the top plate with flippers and stabilzers. NOTE: I did add a few pass through bolts to the middle of the board knowing ahead of time it would be a flimbsy mess without it. This plastic is SO flexible. Its actual a bit comical to type on

The result after assembly

And finally, with one piece keys from another SSK (1397681). If you were wondering, I used the printed Cherry MX mount adapter stem for the Enter/Return key. The adapter looks tilted in the photo, but it is perfectly vertical

The action of the keys on the edges are exactly as I had hoped. SUPER light, crisp, and clean. Almost identical to an F, and light years ahead of my M's. I broke the Kishsaver out to compare, and I can't tell the tactile difference (slight audible difference... but remember, I'm on flimsy plastic for a top and bottom plate). The middle is less enjoyable as expected due to the plate flex. If an audio file is interesting to anyone of the M vs this plastic F, let me know, and I will slap something together

I did make three adjustments to the end design. The first was expected. I had to shorten the spacers on the sides for clearance. It was difficult to gauge that before having something physical in hand, and if we ever want to design our own cases, the full length spacer on each side is definitely desirable. The second was the notch in the backplate for the PCB wired connection. I'm not sure what others are doing in that space, but I removed the portion of the plate applying pressure to the wiring. And lastly... I did make one mistake on key layout. The Right Alt needed to be shifted away from the space bar ~1mm (the keys lightly touch). One other thing, the voltage threshold for the xWhatsit needed to be increased from 116 to 122 after bending the PCB. These capacitive circuits are touchy animals. Hats off again i$ for getting this PCB to work in the first place.

All in all... very pleased with the result, and lack of changes needed. I don't think I am going to wait for any "burn-in" before chatting with metal fabricators. The RFQ (request for quote) process takes several days, but I will report back. I plan on having a metal duplicate made for myself first, and will let everyone know the costs involved on larger quantities. Personal opinion, we are VERY close to making this real.

Started with bending the PCB (I had a REAL need to do so since any undesirable pitch in the PCB alters the entire assembly since the plastic is so flimsy). I have a heat gun (which makes short work of it), and needed the complete curve to be uniform. I used a 4 gallon ceramic crock to achieve the desired bend. Worked beautifully

Spoiler:

Spoiler:

Spoiler:

I did make three adjustments to the end design. The first was expected. I had to shorten the spacers on the sides for clearance. It was difficult to gauge that before having something physical in hand, and if we ever want to design our own cases, the full length spacer on each side is definitely desirable. The second was the notch in the backplate for the PCB wired connection. I'm not sure what others are doing in that space, but I removed the portion of the plate applying pressure to the wiring. And lastly... I did make one mistake on key layout. The Right Alt needed to be shifted away from the space bar ~1mm (the keys lightly touch). One other thing, the voltage threshold for the xWhatsit needed to be increased from 116 to 122 after bending the PCB. These capacitive circuits are touchy animals. Hats off again i$ for getting this PCB to work in the first place.

All in all... very pleased with the result, and lack of changes needed. I don't think I am going to wait for any "burn-in" before chatting with metal fabricators. The RFQ (request for quote) process takes several days, but I will report back. I plan on having a metal duplicate made for myself first, and will let everyone know the costs involved on larger quantities. Personal opinion, we are VERY close to making this real.

- XMIT

- [ XMIT ]

- Location: Austin, TX area

- Main keyboard: XMIT Hall Effect

- Main mouse: CST L-Trac Trackball

- Favorite switch: XMIT 60g Tactile Hall Effect

- DT Pro Member: 0093

I still get spurious key presses with mine, even after removing the rubber mat from the inside of the board, and playing with the xwhatsit settings quite a lot. It seems worse when I'm using a neoprene rubber wrist rest which tells me that there is likely some electrical issue somewhere. I might consider adding more grounding to the entire keyboard somehow.

As a result of the spurious key presses, I'm not using my FSSK much.

As a result of the spurious key presses, I'm not using my FSSK much.

-

hypkx

- Chasing the Dream

- Location: Berlin

- Main keyboard: redscarf III

- DT Pro Member: -

Me two I am still in the progress to eliminate those things, but its more keys that dont work which annoy me. The flickering keys arent current not that bad (I adjusted the software so that the flickering keys dont have any output to the computer), but 3-4 alphas dont work, also the spacebar, pretty annoyingXMIT wrote: I still get spurious key presses with mine, even after removing the rubber mat from the inside of the board, and playing with the xwhatsit settings quite a lot. It seems worse when I'm using a neoprene rubber wrist rest which tells me that there is likely some electrical issue somewhere. I might consider adding more grounding to the entire keyboard somehow.

As a result of the spurious key presses, I'm not using my FSSK much.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

I am so sad to read these posts ...hypkx wrote:Me two I am still in the progress to eliminate those things, but its more keys that dont work which annoy me. The flickering keys arent current not that bad (I adjusted the software so that the flickering keys dont have any output to the computer), but 3-4 alphas dont work, also the spacebar, pretty annoyingXMIT wrote: I still get spurious key presses with mine, even after removing the rubber mat from the inside of the board, and playing with the xwhatsit settings quite a lot. It seems worse when I'm using a neoprene rubber wrist rest which tells me that there is likely some electrical issue somewhere. I might consider adding more grounding to the entire keyboard somehow.

As a result of the spurious key presses, I'm not using my FSSK much.I hope I cant fix this. I dont use any rubbermad, between the pcb and the flippers.

I do not get any spurious key presses. With none of the two keyboards that I have. And they are my only keyboards, in the office and at home.

It could be related with the way that you have wired the controller and the PCB. In my pictures you can see that I have been VERY careful with the ribbon, and ensured that rows and columns are separated by GNDs and terminated also with two GNDs

- XMIT

- [ XMIT ]

- Location: Austin, TX area

- Main keyboard: XMIT Hall Effect

- Main mouse: CST L-Trac Trackball

- Favorite switch: XMIT 60g Tactile Hall Effect

- DT Pro Member: 0093

Well, I'm just as sad to write mine.

From my photos earlier (post303298.html#p303298) you can see how I connected the xwhatsit board to my PCB. There are a few possible improvements there:

- I did not modify my plate for the FSSK PCB as some others did. Perhaps removing the backing plate from the back side of the board where the connector is, could help;

- the ribbon cable could be shorter, and the wires could be the same length;

- grounding the case itself, to prevent static discharge;

- using a grounded Space bar from a Greenock M to battle charge buildup.

In general, I find that any keyboard with the xwhatsit is incredibly finicky. I don't use my DisplayWriter much for the same reason: I need to thoroughly clean it to see if that might help. The F107 I have is probably the best behaved xwhatsit board I own.

From my photos earlier (post303298.html#p303298) you can see how I connected the xwhatsit board to my PCB. There are a few possible improvements there:

- I did not modify my plate for the FSSK PCB as some others did. Perhaps removing the backing plate from the back side of the board where the connector is, could help;

- the ribbon cable could be shorter, and the wires could be the same length;

- grounding the case itself, to prevent static discharge;

- using a grounded Space bar from a Greenock M to battle charge buildup.

In general, I find that any keyboard with the xwhatsit is incredibly finicky. I don't use my DisplayWriter much for the same reason: I need to thoroughly clean it to see if that might help. The F107 I have is probably the best behaved xwhatsit board I own.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Bummer...

Where I would focus...

Not saying this is the problem in any way, but 99% of my problems have always been related to the voltage threshold on the xWhatsit. Too low, and some keys don't register, too high, and unwanted key strikes occur (and vis versa depending on the direction of voltage you are coming from). I find it best to literally set it 1-3 points over where errand keys are being pressed. The lower the voltage, the more precise for me (especially with the beamsprings)

Side note... someone should rewrite the xWhatsit front end. There are several tweaks that would be very desirable (ie... being able to key in the voltage. If you ever have to actually hit 'Emergency Halt', God be with you for the next several minutes while you manually roll down the volts using cursor arrow from 24k (or whatever it is) to 150 . I have 10+ tweaks like this that need to be made. Brilliant device and hardware... BOO to the UI

. I have 10+ tweaks like this that need to be made. Brilliant device and hardware... BOO to the UI

I doubt it in your case since you mounted directly to the top of the PCB vs. coming up from underneath. It would probably make sense to make sure the eyelets (PTH) are not contacting the backplate, but you have Kapton insulating. Another layer of electrical tape there would be my first attempt since it is easy

That feels like a reach myself... My ribbon is the same length for each strand, and i$ made his a little prettier configuration with varying lengths. These run lengths matter, but not that closely (at least not if multiple keys are acting up)

Mine is completely ungrounded. I took a note from Soarer on this one a while ago. The grounding through the USB is a ton. It's never a bad idea to augment, but seldom the culprit

Where I would focus...

Not saying this is the problem in any way, but 99% of my problems have always been related to the voltage threshold on the xWhatsit. Too low, and some keys don't register, too high, and unwanted key strikes occur (and vis versa depending on the direction of voltage you are coming from). I find it best to literally set it 1-3 points over where errand keys are being pressed. The lower the voltage, the more precise for me (especially with the beamsprings)

Side note... someone should rewrite the xWhatsit front end. There are several tweaks that would be very desirable (ie... being able to key in the voltage. If you ever have to actually hit 'Emergency Halt', God be with you for the next several minutes while you manually roll down the volts using cursor arrow from 24k (or whatever it is) to 150

- pyrelink

- Location: USA

- Main keyboard: HHKB 2

- Main mouse: CST L-Trac

- Favorite switch: Capacitive Buckling Spring

- DT Pro Member: -

I still have yet to put together my FSSK, but to comment on my experience with xwhatsits converters: proper voltage threshold and grounding have always been my primary issues. On my F107, my voltage threshold can't go any higher as I get a bunch of random keypresses and lower, and keys don't register. And even then typing really quickly will start getting random keystrokes.

Getting beefier grounding with better connections drastically improved random keystrokes. Still isn't perfect but just some anecdotal evidence for working on your grounding.

And I agree that the UI and software could use an update. At present the Mac software is very volatile and results in quite a few freezes or crashes or required force quits, based on the buttons you might press.

Getting beefier grounding with better connections drastically improved random keystrokes. Still isn't perfect but just some anecdotal evidence for working on your grounding.

And I agree that the UI and software could use an update. At present the Mac software is very volatile and results in quite a few freezes or crashes or required force quits, based on the buttons you might press.

-

hypkx

- Chasing the Dream

- Location: Berlin

- Main keyboard: redscarf III

- DT Pro Member: -

I think I will try to add more grounding, or in general add any grounding than the two cables  , btw I have such a greenock model m with grounded spacebar, but I thought that the wire do nothing because its a plastic spacebar?

, btw I have such a greenock model m with grounded spacebar, but I thought that the wire do nothing because its a plastic spacebar?

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

The feeling is mutual.

I did just send off for the metal cutouts since I don't have easy access to a water/laser jet cutter. 190 holes for a single top plate is more than my little mind can process on a drill press

i$ and I are starting discussions about a GB. This is basically the equivalent of the the Ellipse F62/77 project (minus the case), so we might need a little bit to work out the dynamics. There are things to consider like shrinking the PCB to its minimum, altering the top plate to match the form factor, using the model M xWhatsit (if available), etc. Patience is appreciated. We are inching closer though

EDIT: This is an absolute horrid rendering from Big Blue Saw, but might be interesting to some. The prototype top and bottom plates will be .048 inch cold rolled carbon steel (18 gauge = 1.2mm). I will blast and paint (matching the color scheme of the plastics) both plates after I roll and break them. Unless we decide to change the barrel "lock" from a peg to something else... this will be the final design

Spoiler:

Last edited by lot_lizard on 19 May 2016, 04:27, edited 1 time in total.

- pyrelink

- Location: USA

- Main keyboard: HHKB 2

- Main mouse: CST L-Trac

- Favorite switch: Capacitive Buckling Spring

- DT Pro Member: -

Very exciting news, and incredible work coming out of you guys here. You can count me in for what ever kit you guys wind up putting together. Any hints as to whether it would be worth working on accumulating more XT barrels and and flippers, or are those both things you plan to have covered?

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

If we get real interest in this, I would like to see the barrel and flipper prints I put together work out (they deliver around the end of the month from Shapeways in HD print to test dimensions and functionality... along with the Cherry MX conversion key stems).

I am actually the one yahoo on planet earth that truly loves the Bigfoot, and would hate to see potentially dozens of XT's and Bigfeet sacrificed. I am confident in the designs of the barrels/flippers, and will need to work out a conductive plastic to mold them with, but I have checked on pricing... and it is trivial in any real bulk (10+ boards). I did send off a flipper to the local lab to have FTIR tested (link at the base of this post if curious what that is) to see what these things are REALLY made of. We have speculated, and I did ask around, but no one has ever actually tested one that I can find. The F62/77 project is using a conductive ABS (which these might be just that), but I would like to get it right without question. I have tested the resistance myself using nicer equipment, but it is still a crude method compared to the FTIR.

But... having said all of that. It wouldn't be a bad idea to have an XT/Bigfoot (plus one flipper, and two barrels) on hand

https://en.wikipedia.org/wiki/Fourier_t ... ectroscopy

EDIT: The springs are nothing special, and very inexpensive to produce in bulk (neighborhood of a dime USD a pop). It is just a matter of diameter of the spring (OD and ID), coil count, length, and material. Keep in mind that literally 2 boards has us in "bulk pricing" because of the number of keys (84). It's goodness...